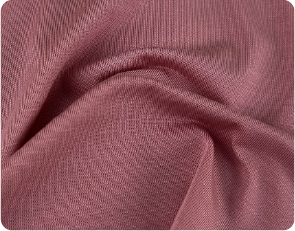

World Class Textile Producer with Impeccable Quality

-

Proven Quality with Technical Expertise

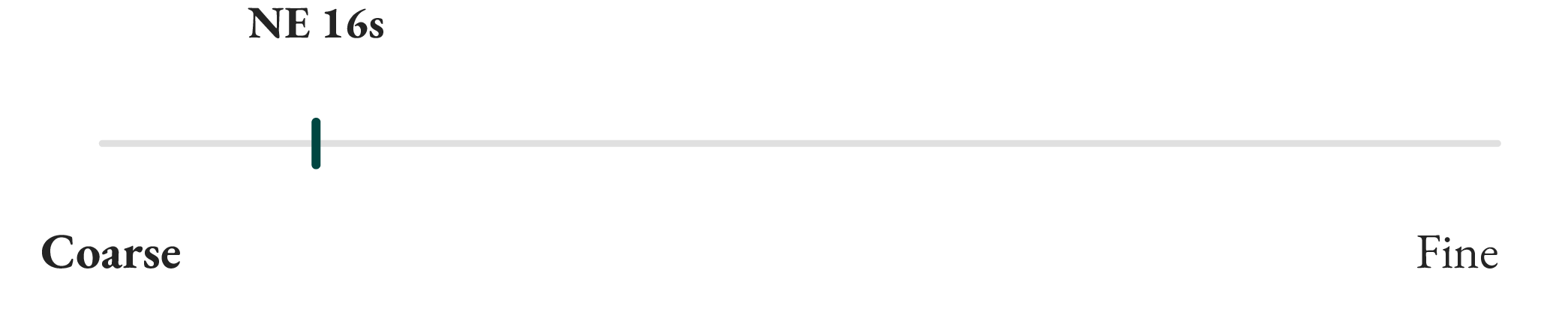

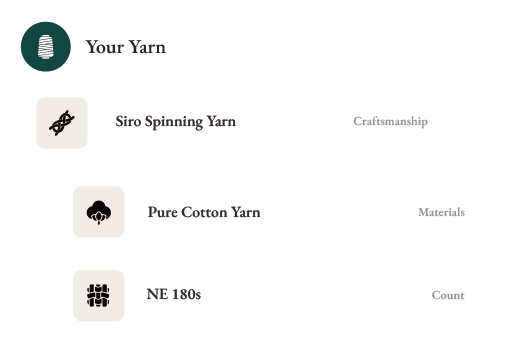

As a well-established textile supplier, the most valued aspect must be the quality of the yarn. With more than 15 years of experience in yarn development, we have continuously improved the Vortex spinning process to produce Vortex yarn of impeccable quality. Whether it's evenness, hairiness, or functional tests such as moisture wicking, we can guarantee it with care.

-

Integrated Manufacturing from Yarn to Fabric

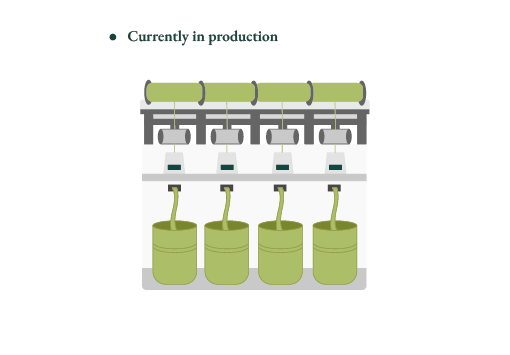

We maintain full control over every stage of production—from raw fiber selection to Vortex spinning, dyeing, and fabric finishing. Every batch of yarn we produce is high quality and traceable.

-

Customization and OEM Support for Global Brands

Whether you want to develop high-performance or basic garments or make textiles for home or industrial use, our team of specialists will analyze the situation and work closely with you to provide OEM solutions.