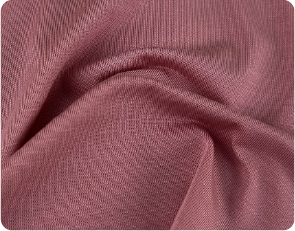

World Class Textile Producer with Impeccable Quality

-

Superior Strength and Durability

Ring spun yarn is a very classic spinning process in which fibers are continuously twisted and stretched. The result is a tightly packed yarn with excellent tensile strength, which makes it very durable for further processing and for wearing as fabric.

-

Customization and Technical Expertise

We support a selection of 100% cotton, organic cotton, spandex, modal, or other functional fibers, with a wide range of yarn stocks and types to meet your different sourcing needs as well as special customization requirements.

-

Commitment to Quality and Sustainability

All Ring spun yarns are produced under strict quality control protocols, with full traceability and test data available upon request. We offer GOTS, GRS, and OEKO-TEX certified yarns for eco-conscious brands, and actively invest in sustainable materials and closed-loop processes to support responsible production across the textile supply chain.