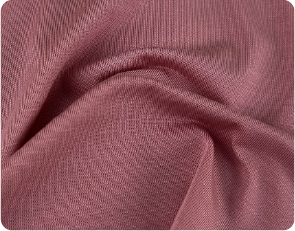

World Class Textile Producer with Impeccable Quality

-

Proven Expertise in Open-End Yarn Manufacturing

With over 15 years of yarn experience, we specialize in producing open-end spun yarns for diverse end uses, including denim, towels, home textiles, and workwear. Our technical know-how ensures reliable performance across all applications.

-

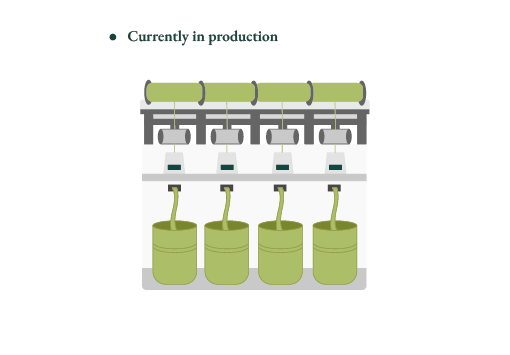

Stable Supply with Competitive Pricing

Our Open-End Spun Yarn production process is streamlined and efficient, and our yarn factory is vertically integrated to maintain a consistent supply and production. This also allows us to offer consistent quality, competitive pricing, and dependable delivery for long-term partnerships.

-

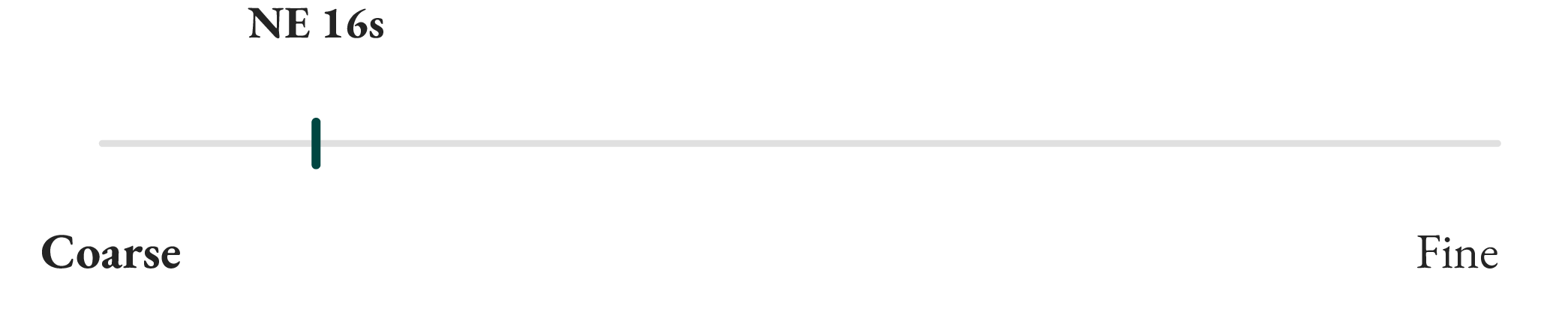

Customized Yarn Specifications on Demand

We offer a fully customised service, including yarn count and fiber composition to twist and dyeing options or any other. Whether you need conventional cotton yarn or recycled Open-End Spun Yarn, we can tailor solutions to meet your needs.