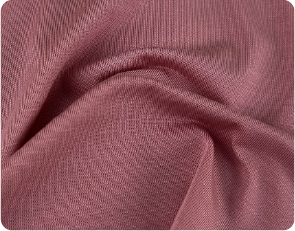

World Class Textile Producer with Impeccable Quality

-

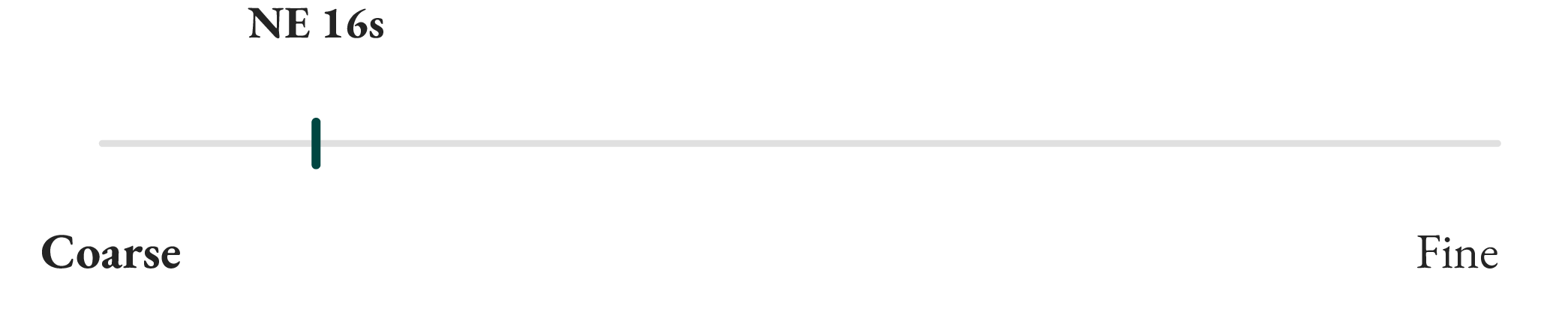

Advanced Compact Spinning Technology

We use state-of-the-art Compact yarn manufacturing equipment and processes to provide customised Compact yarn with high quality, low linting, and uniform smoothness according to your project and application.

-

Customized Solutions for Diverse Applications

Whether it's textile mills, apparel manufacturers, or brand sourcing, we're all very familiar with it. We can offer different fibre blends, yarn counts, and other customisation options to target yarns according to fabric type and application.

-

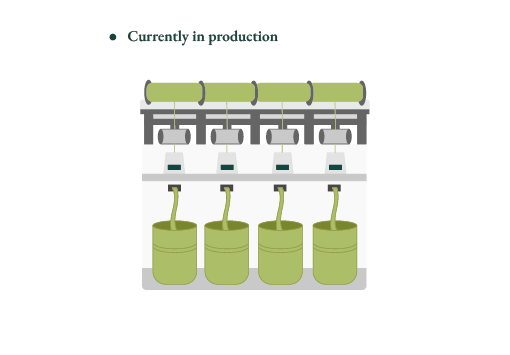

Reliable Supply and Competitive Pricing

With a robust production capacity and streamlined supply chain, we guarantee timely delivery and stable inventory levels to support your manufacturing schedules. Our pricing is competitive without compromising quality, providing excellent value for bulk orders and long-term partnerships.